Maximum safety

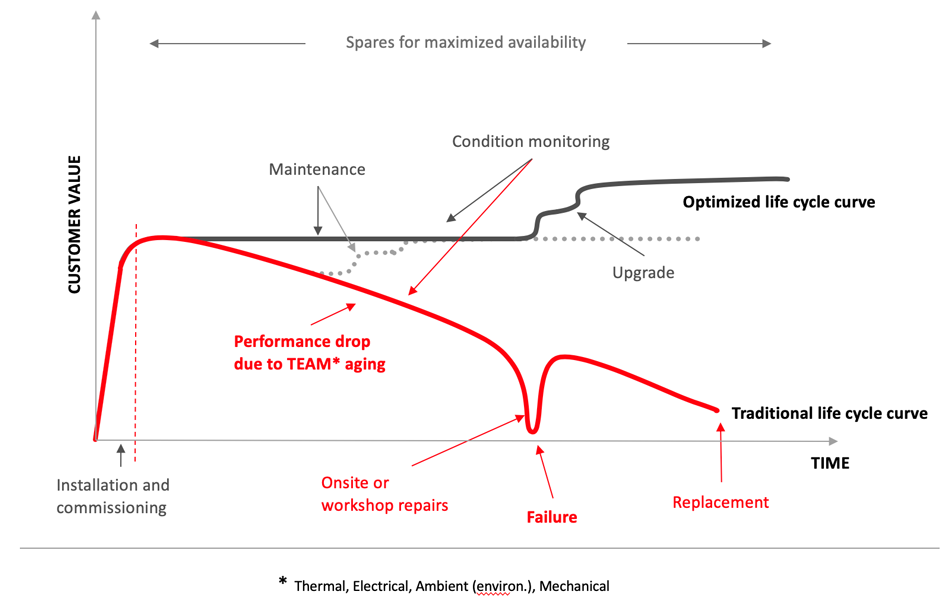

We provide safety by active prevention and fast response in the event of an emergency. Our goal is to maintain your electrical machines’ productivity throughout their entire life cycle.

Continued operability

We offer our customers a comprehensive service program, safeguarding the operability of their electrical machines.

Troubleshooting

From installation and commissioning to maintenance, safety checks and overhaul up to enhancement and optimisation.