maintaining mechanical strength

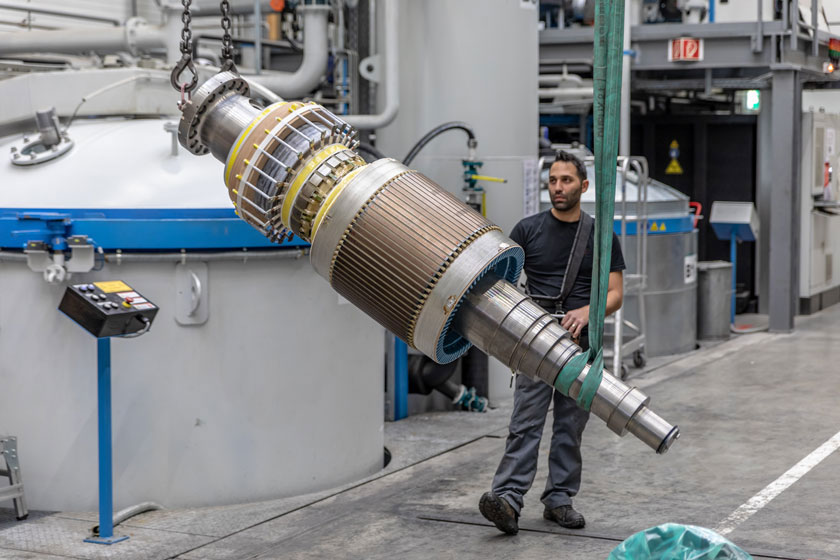

Vacuum pressure impregnation

Impregnation is crucial for both mechanical and electrical strength. Different types of resin are used for the different impregnation methods.

To achieve optimum manufacturing results, we support you in the selection of methods and resins.

The VPI method ensures maximum availability of the machine.