In an area of more than 6000 m2

Production facilities

Infrastructure

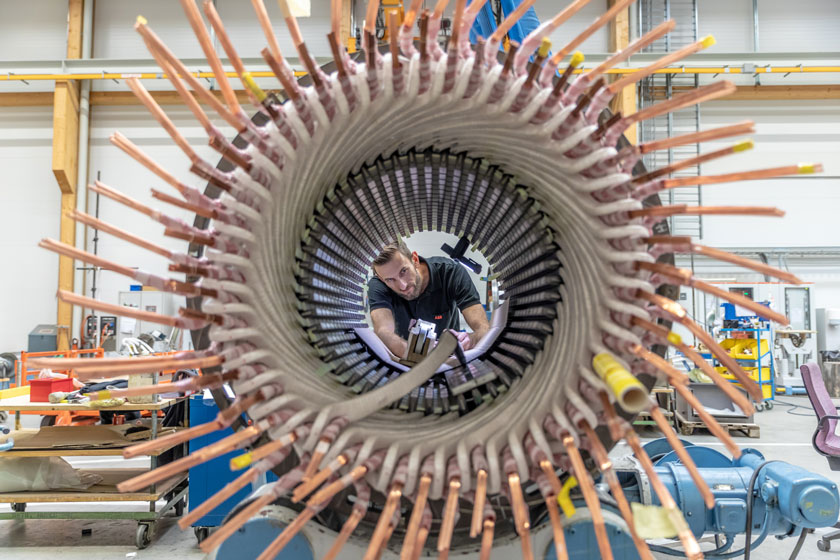

At Birr Machines we have highly professional production facilities , at our disposal, facilitating comprehensive, high-quality work.

Your advantage: We have a production area of more than 6000 m2 at our disposal. Our technical methods and procedures enable both small and large-scale revision of motors up to 80 tonnes.

At the forefront: With our large, separate test facility (16 m x 9 m), which we have taken over from ABB, we are among Europe’s top providers.