Customer-specific projects

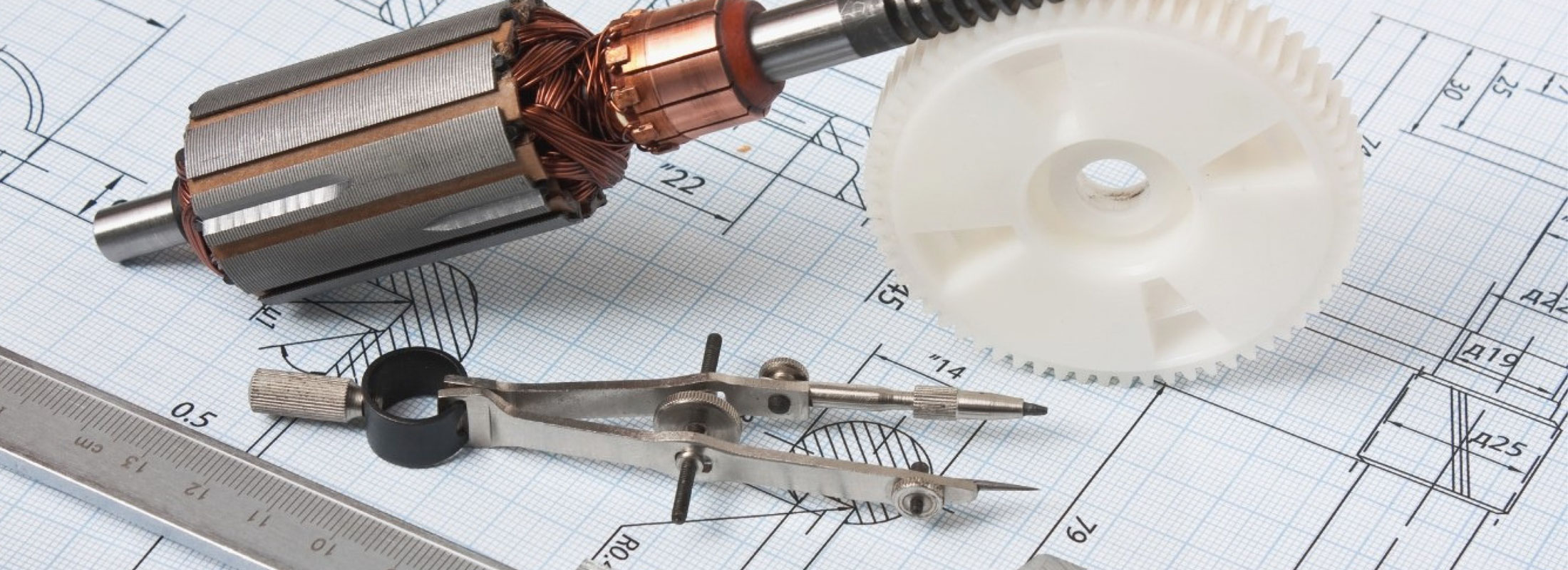

Design & Engineering

Electrical calculation

- Testing the electrical design.

- Adaptation to new operating conditions.

- Optimisation of the electromagnetic and thermal capacity (stator, cooler, rotor)

Mechanical calculation

- Torsion and lateral vibration analysis of the shaft train (rotor dynamics)

- Structural mechanics and modal analysis (FEM)

- Vibration measurements

Construction

- Design for speeds up to 7,200 rpm

- Customer-specific motor dimensioning upon request

- Customer-specific interface design